Author Archives: Mila Clement

Annealing Capabilities

- In Atmosphere “Air”

- In N2 Environment

- Stabilize up to 450C

GDSI

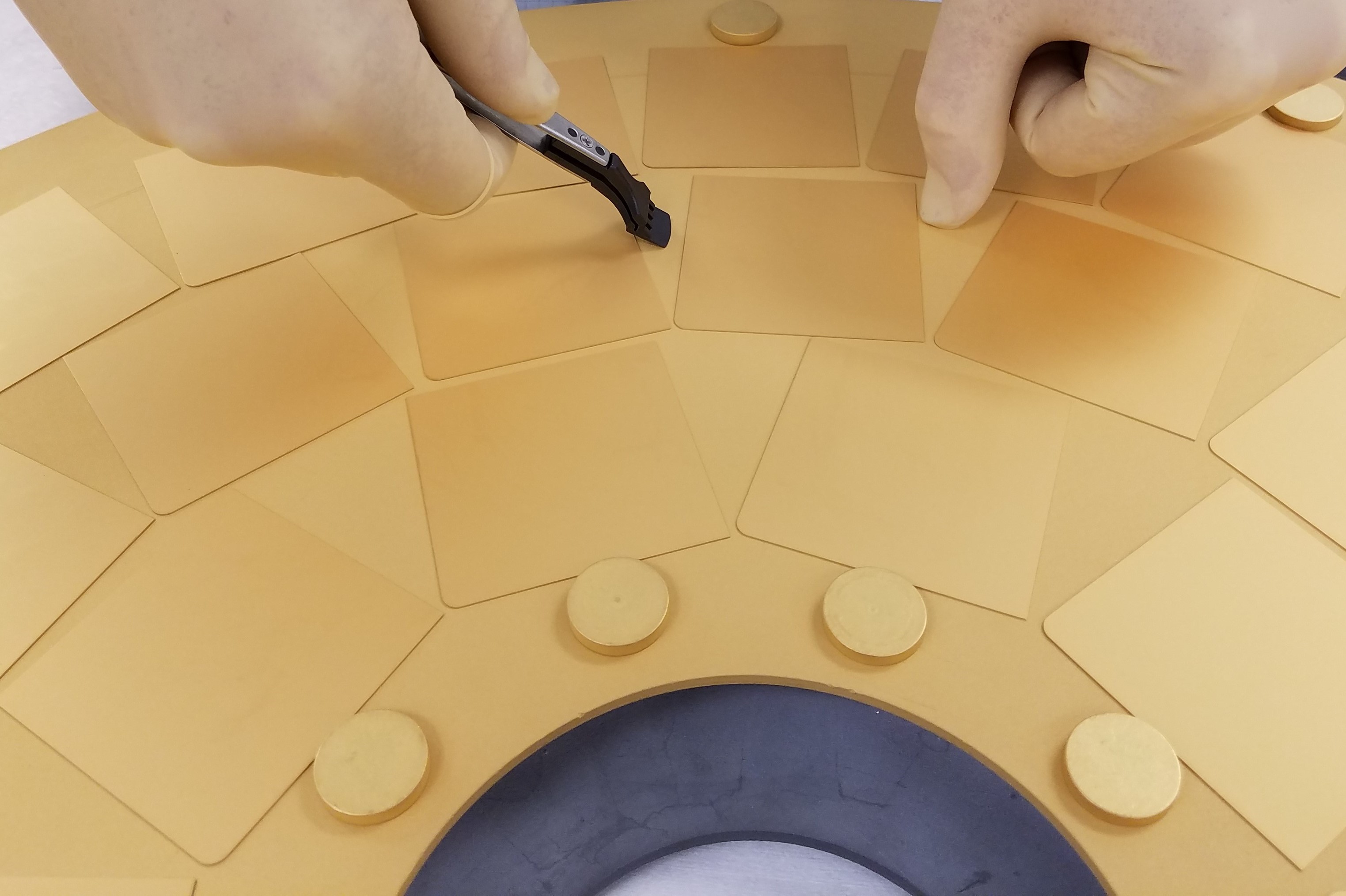

“GDSI Provides outsourced engineering services to integrated device manufacturers and fabless semiconductor companies. GDSI ofers wafer backgrinding, polishing, dicing, die sort and inspection with quick turnaround times.”

Surplus Equipments For Sale

KLA/Tencor Sigma Scan 1ea

KLA/Tencor Alpha Step 200 1ea

CTI On Board 8 Cryo pump 1ea

Advanced Energy MDX DC 5K Power supplies 2ea

CTI SCW Cryo Compressor 1ea

Granville Phillips 270 Gauge Controller 1ea

Granville Phillips 260 Gauge Controllers 2ea

Varian TSP Control Unit 1ea

Career Opportunities

It’s an exciting time to join UHV, one of the nations most innovative vacuum coating services. We’re ushering in a new era to help our customers meet the enormous challenges in the custom thin film coating industry. If you’re considering career opportunities with UHV, consider the following:

- We’re a proven and stable company with decades of success.

- We offer career opportunities in Morgan Hill, CA.

- You’ll be part of a innovative team of professionals.

- We provide opportunities for professional growth and promotion-through both on-the-job mentoring and training programs.

- We’re built on a framework of teamwork, ensuring our employees have the resources they need to get the job done right. At the same time, we celebrate individual accomplishments and successes.

- We support a culture of caring and a tradition of service excellence.

- We offer a full spectrum of employee benefits as part of our compensation package.

- We work to do the right thing for all our customers and our employees.

If being a part of our team seems like the right opportunity for you, please email your resume to info@uhvsputtering.com, we will contact you for possible interview when a fitting position is available. Thank you for your consideration.

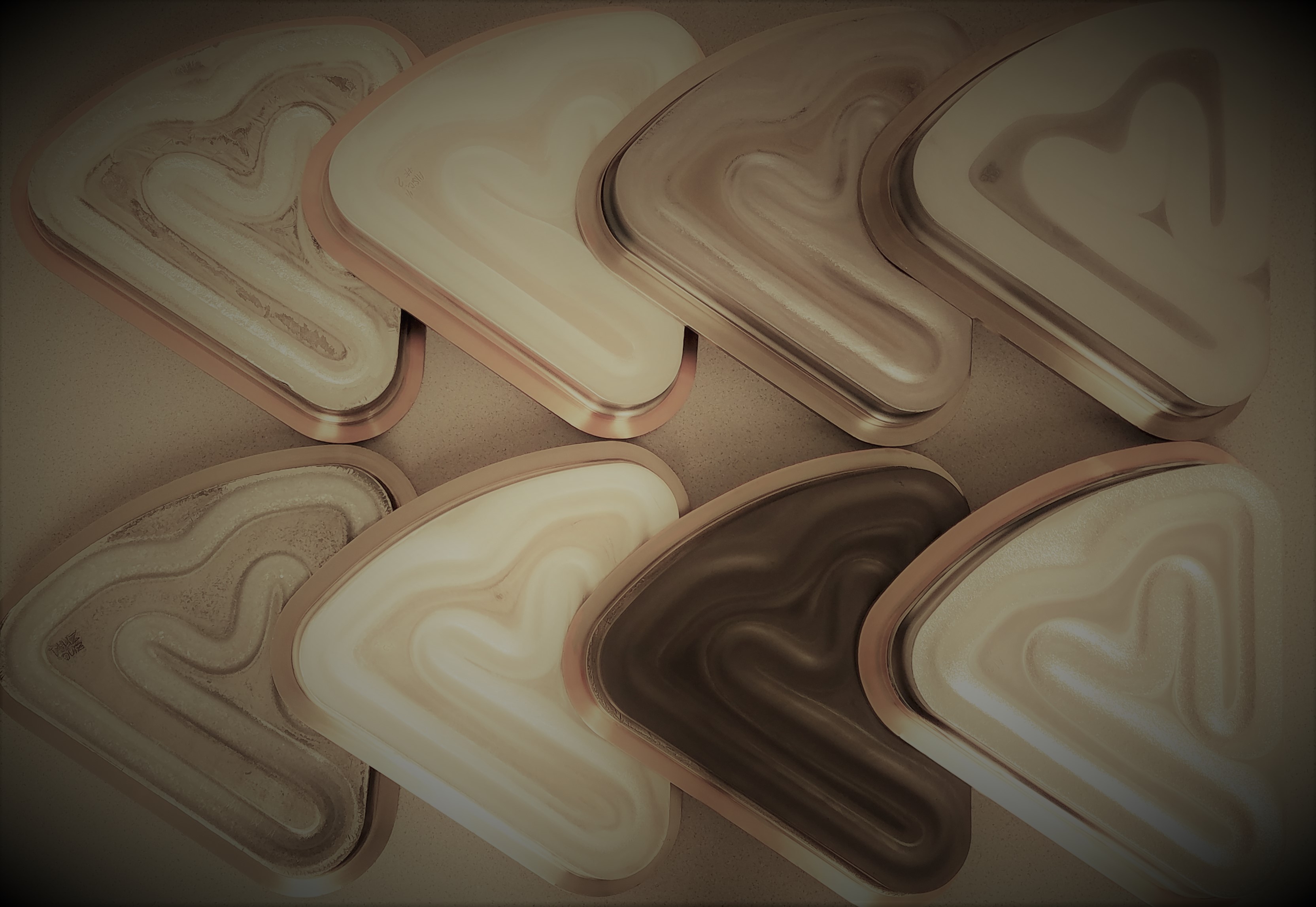

Bonding Services

UHV Sputtering offers a high quality target bonding service as well as a wide range of sputtering materials. We specialize in bonding, employing state of the art Metalization Techniques. UHV utilize a variety of solder materials, which serve to interface the target and backing plate. These materials accommodate the various thermal and mechanical stresses that are characteristic in today’s sputtering equipment.

UHV custom tailors it’s bonds to meet each customers specific needs. For example, systems with high power density levels often require high temperature solder materials, while cathode designs with a severe mismatch in expansion rates achieve optimum performance with a more ductile material, such as indium.

Our materials consists of different sputtering target materials using the latest manufacturing methods, Hot Pressed, Sintured, Cold Isostatic Press, Hot Isostatic Press and sometimes a combination of these.

For more information, please contact our sales staff for more details or submit an RFQ.

Request A Quote For Sputtering

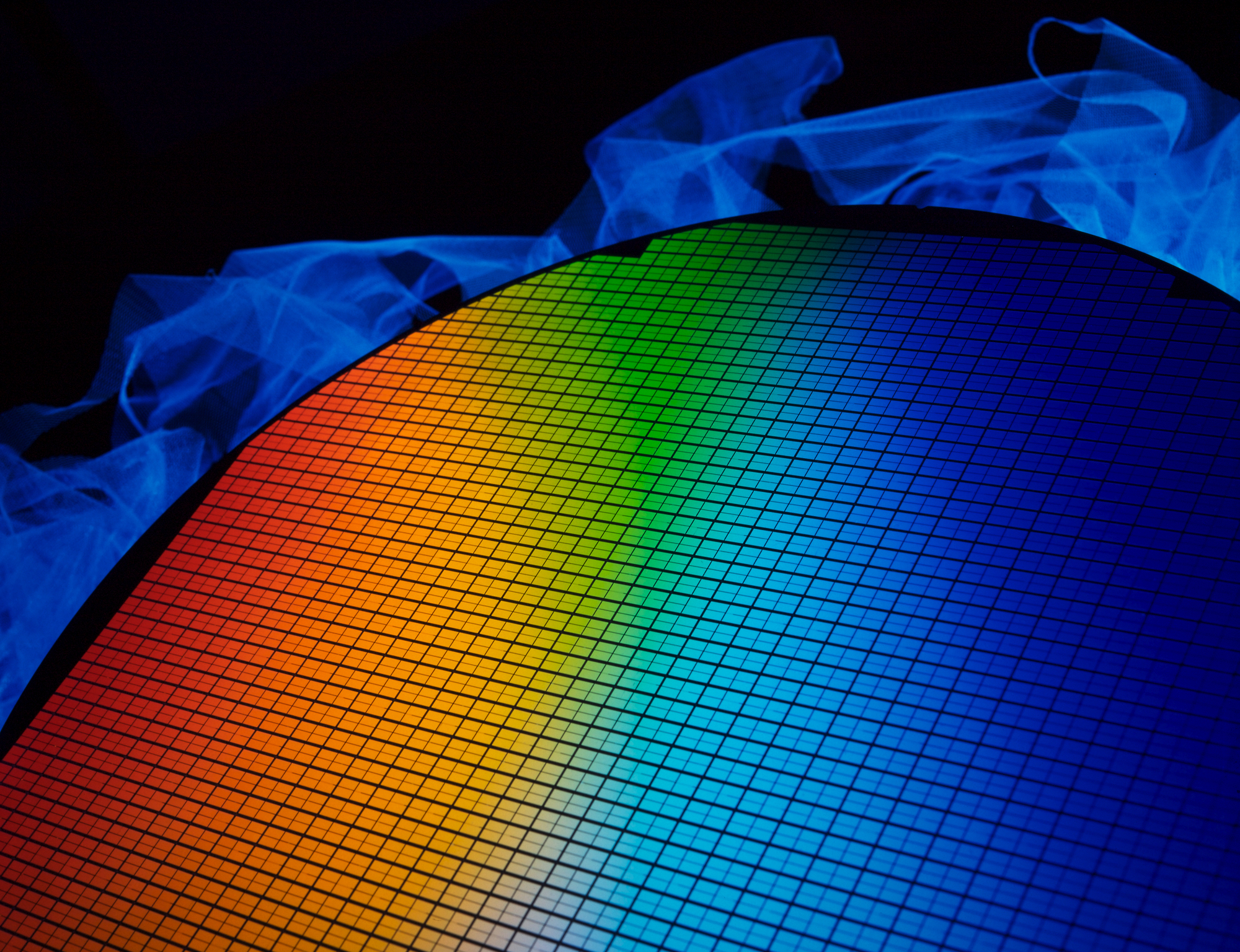

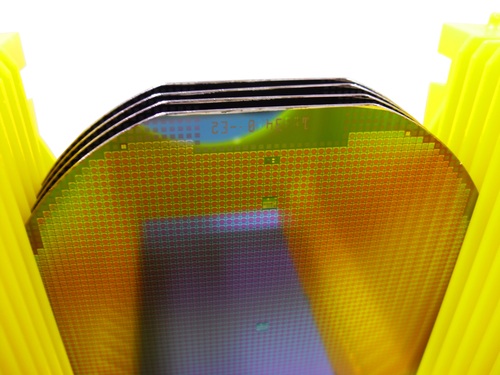

UHV Sputtering offers a physical vapor deposition (PVD) method for custom thin film coatings, using DC and RF magnetron sputtering. We process up to 300mm diameter and custom sizes. Please fill out the quote form with your requirements and a sales representative will respond in a timely manner.

Request A Quote For Bonding

UHV Sputtering offers a wide inventory of sputtering target materials. Process capability includes DC and RF magnetron sputtering. We process up to 12″ diameter wafer as well as numerous other substrate materials. Our coatings are achieved under tight controls in a clean room environment, using completely refurbished, late model vacuum equipment.

Error: Contact form not found.

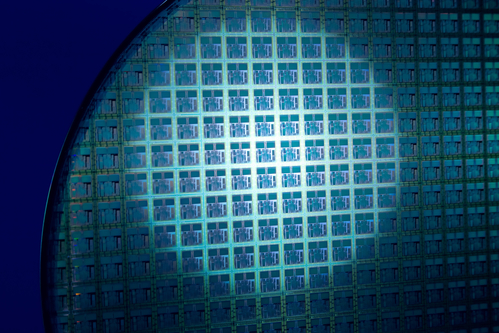

Sputtering Services

Some Industries we serve include:

And many more….

UHV Sputtering offers a wide inventory of sputtering target materials. Process capability includes DC and RF magnetron sputtering. We process up to 300mm diameter wafers as well as numerous other substrate materials and custom sizes. Our coatings are achieved under tight controls in a class 100 clean room environment, using completely refurbished vacuum equipment.

Processing capabilities include PVD sputtering:

Processing capabilities include PVD sputtering:

- Dielectrics

- Resistors

- Conductive layers

- Insulators

- Noble films

- And many others, over 60 materials in stock

Annealing Capabilities

Annealing Capabilities

- In Atmosphere “Air”

- In N2 Environment

- Stabilize up to 450c

System Compatible Materials

System Compatible Materials

- Substrates

- Alumina (Al2O3)

- Fused Silica

- Aluminum Nitride (AlN)

- Berillium Oxide (BeO)

- Vias

- Ferrite

- Graphite

- Si or Glass wafers (25mm – 300mm)

- Bare or with Thermal Oxide

- Pattern

- Photo Resist

- Polymers (high temp)

Please contact us for all other materials and custom sizes.

Typical Specifications

Typical Specifications

- Film thicknesses up to several microns on most materials.

- Film thickness are determined by mechanical surface profilometer

- Film uniformity: +/-5% (may vary per requested thickness and film)

- Resistance uniformity: +/- 10% window

- Target sheet resistance range from 20 Ω/sq – 150 Ω/sq

Please contact us for all other capability information.

For more information, please contact our sales staff or submit an RFQ